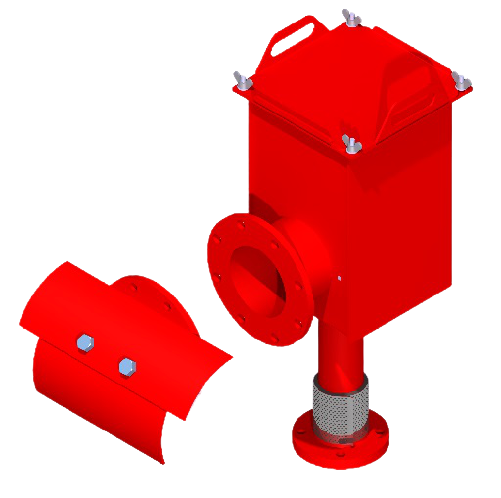

Foam chambers consist of a foam expansion chamber and an integral foam maker with a stainless steel screened air inlet. Each chamber includes an orifice plate, two inlet gaskets, vapor seal assembly, cover gasket, and an outlet gasket. The required deflector (split or shallow) and optional mounting pad assembly are sold separately.

A removable orifice plate located at the flanged inlet to the foam maker is sized to deliver the required flow rate of foam solution at a specified inlet pressure. A frangible Teflon vapor seal is burst upon entry of foam solution allowing an unrestricted flow of expanded foam into the chamber body. From the chamber body, the foam flows through the foam deflector which disperses the foam into the storage tank.

The chamber vapor seal is accessible for inspection and service through a hinged inspection hatch that is secured with captive bolts. The hatch also contains a lifting handle that is designed to support the weight of the foam chamber.

The foam deflector directs the foam stream down the tank sidewall to lessen the submergence of the foam and agitation of the fuel surface. The foam deflector is a split (two-piece) style. The split deflector allows for either bolting or welding to storage tanks when installation may be performed from both sides of the tank wall as with newly constructed tanks. The split deflector also allows for insertion of the deflector through the flange opening from the outside wall as is often required with tanks already in service. The foam chamber and deflector can be bolted to the storage tank using a mounting pad. The pad contains mounting studs to fit standard flange holes.

Our Products

|

Features

Reference: NFPA 11 Inlet Connection: ASME B16.5 Flange #150 Outlet Connection: ASME B16.5 Flange #150 Inlet Size: 2” – 2,1/2” – 3” Outlet Size: 4” – 6” – 8” Material:

Mesh Plate Material: Stainless Steel Thickness: 3 mm Operating Pressure:3-8 bar Design Pressure:12 bar Finish Paint: Polyurethane Red RAL 3000 Accessories:

|