A Fire Pump is a part of a fire sprinkler system’s water supply and powered by Electric Pump, Diesel or Steam Pump and Jockey Pumps.

Fire pumps are needed when the local municipal water system cannot provide sufficient pressure to meet the hydraulic design requirements of the fire sprinkler system. This usually occurs if the building is very tall, such as in high-rise buildings, or in systems that require a relatively high terminal pressure at the fire sprinkler in order to provide a large volume of water, such as in storage warehouses. Fire pumps are also needed if fire protection water supply is provided from a ground level water storage tank.

The fire pump starts when the pressure in the fire sprinkler system drops below a threshold. The sprinkler system pressure drops significantly when one or more fire sprinklers are exposed to heat above their design temperature, and opens, releasing water. Alternately, other fire hoses reels or other firefighting connections are opened, causing a pressure drop in the firefighting main.

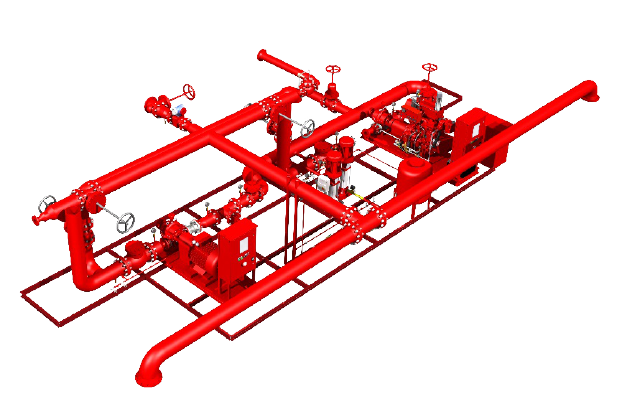

The pump intake is either connected to the public underground water supply piping, or a static water source (e.g., tank, reservoir, lake). The pump provides water flow at a higher pressure to the sprinkler system risers and hose standpipes.

Various types of fire pumps are used in fire protection systems. Types of fire pumps include: Horizontal Split Case, Vertical Split Case, Vertical In-line and Vertical Turbine. These fire pumps may be powered by an electric motor or diesel engine and on rare occasion powered by a steam turbine.

|

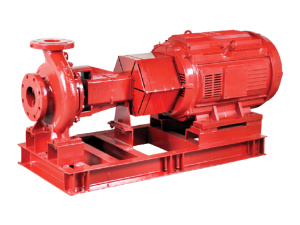

Horizontal Split CaseThe horizontal split case fire pump is the most common type for commercial buildings. It’s easy to use and maintain, so fire protection technicians prefer this option. It will need an external water source, but this isn’t a huge concern. Plus, it’s an extremely durable and reliable fire pump, making it a top choice. |

|

Vertical Split CaseThe vertical split case fire pump is similar to the horizontal split case pump, but they take up less space because they’re vertical. If space is an issue in your building, then this might be the most viable option. Not to mention, because the pump is vertical, it reduces the risk of the motor flooding, which is one of the main benefits. |

|

Vertical In-lineThe vertical in-line fire pump is smaller and more compact than the split fire case pumps. This means you can save even more space, which is ideal for small companies and buildings. The main issue with these pumps is that you have to disassemble and remove the entire system when it’s time for a maintenance/service. |

|

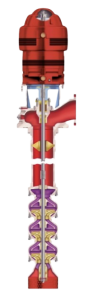

Vertical TurbineThe vertical turbine fire pump can use water from nearby wells or tanks. Unlike the other fire pumps, it can operate without priming. It works by moving water up through the column pipe. Then the water stays at the top of the pump so it can be dispensed when needed |

Special Application

|

Jockey PumpA Jockey Pump is a small pump connected to a fire sprinkler system and is intended to maintain pressure in a fire protection piping system to an artificially high level so that the operation of a single fire sprinkler will cause a pressure drop which will be sensed by the fire pump automatic controller, causing the fire pump to start. The jockey pump is essentially a portion of the fire pump’s control system. A jockey pump is sized for a flow less than the flow to one sprinkler in order to ensure a system pressure drop. Jockey pumps are typically small multistage centrifugal pumps, and do not have to be listed or certified for fire system application. The control equipment for jockey pumps may however carry approvals. Jockey pumps should be sized for 3% of the flow of the main fire pump and to provide 10psi more pressure than the main fire pump (As per Code IS 15105: 2002) |

Applicable Notes

What are the Differences Between Electric and Diesel Fire Pumps?Both Electric and Diesel Fire Pumps provide fire sprinklers throughout a facility with adequate water supply during a fire. So, what are the differences between electric and diesel fire pumps? Some of the key differences between electric and diesel fire pumps include their applications, maintenance and cost, and lifespan. |

Electric vs. Diesel Fire Pump ApplicationsDiesel fire pumps are ideal for applications when there’s already a separate pump house or the pump room is located on an exterior wall. Some facilities that use diesel fire pumps include warehouse, aircraft hangars, and industrial facilities. Since their footprint is larger than an electric fire pump, they’re not suitable for facilities with minimum space. Unlike diesel pumps, electric fire pumps can be located within the building. Office buildings and condominiums are often equipped with electric fire pumps. Additionally, high rises sometimes install an additional electric fire pump above the ground or basement level to increase water pressure. |

Maintenance and Cost Electric vs. Diesel Fire PumpOne of the important differences between electric and diesel fire pumps is the cost. Diesel fire pumps are more expensive to install because they require additional items such as fuel storage tanks and exhaust ventilation. In terms of maintenance and lifetime cost, electric fire pumps require dedicated electrical service and have higher electrical costs than a diesel pump. But diesel fire pumps require regularly inspecting batteries, oil level, cooling system, hoses, and engine in addition to a weekly run test. Overall, diesel fire pumps cost more because they’re serviced more frequently and have more items to maintain. Also, keep in mind the cost of fire pump preventative maintenance is extremely affordable whereas cutting back on regular service results in costly repairs and replacements. |

Lifespan Differences Between Electric and Diesel Fire PumpsAs mentioned, electric fire pumps require much less maintenance compared to diesel pumps. Since diesel fire pumps have more components that require service, there’s a lot that can go wrong. Neglecting to service these items could shorten its lifespan much more so than an electric fire pump. |

Our Services

SISICO is able to offer an extensive range of Fire Pumps to suit your specific environment from below mentioned companies:

Our Products

|

General

Technical data

Accessories

|