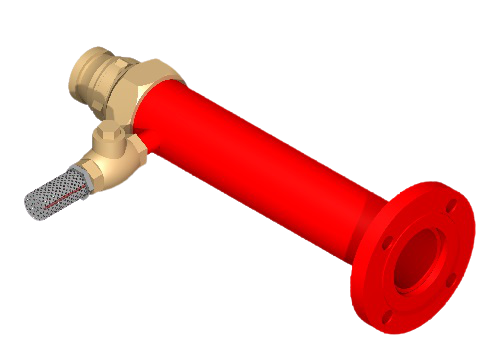

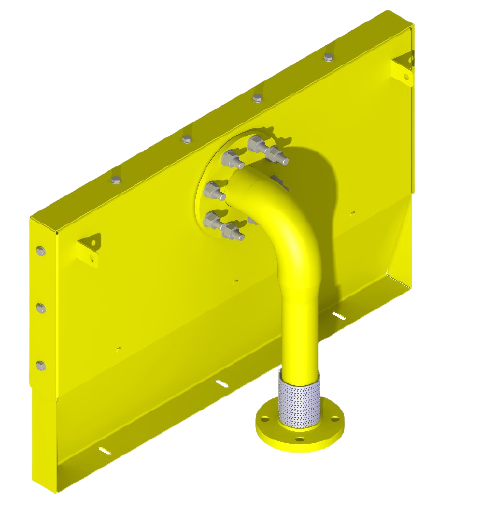

The Rim Seal Foam Pourer is designed to discharge fully aspirated foam directly to the annular seal area of the open top floating roof storage tanks for fire or vapor suppression. Fully aspirated foam provides the most effective performance for all types of foam concentrates.

The rim pourer design provides protection from the wind, allowing the aspirated foam to gently discharge onto the protected area of the floating roof tank. Gentle application minimizes submergence and agitation, increasing the effectiveness of the foam blanket. This design allows a uniform and cohesive foam flow.

|

The cover of the unit, opposite of the foam solution inlet, is designed for removal to allow for internal inspection. The unit can be mounted on the top flange of the fuel storage tank utilizing the mounting holes located in the base of the rim seal foam pourer or by the use of clamps.A screened air inlet, conforming to the cylindrical body, allows uniform air distribution into the foam solution stream to generate expanded foam. This design also helps prevent damage and inhibits the entrance of foreign materials.

A removable orifice plate at the threaded inlet is sized to deliver foam solution over a range of flow rates depending on the inlet pressure. The acceptable operating pressure range is 30 psi to 150 psi (2.1 bar to 10.3 bar). A stainless steel foam solution strainer is provided at the foam maker inlet. The strainer is secured by a snap retaining ring to allow removal for inspection and cleaning. Typical areas of Foam System used:

|

Our Products

Foam systems are designed, tested and manufactured by SISICO and this Company reflects decades of experience in fire suppression technologies and applications.