Fire and Gas System or F&G System continuously monitors for abnormal situations such as a fire, or combustible or toxic gas release within the plant; and provides early warning and mitigation actions to prevent escalation of the incident and protect the process or environment. By implementing an integrated Fire and Gas strategy based on the latest automation technology, plants can meet their plant safety and critical infrastructure protection requirements while ensuring operational and business readiness at project start-up.

The objective of Fire & Gas Detection system is to:

- Minimize the risk and consequences of an accidental event.

- Minimize the potential for hazardous occurrences

- Ensure a safe working environment for personnel

- Ensure adequate means of escape are provided

- Provide sufficient safety devices and redundancy to detect, isolate and minimize uncontrolled releases of flammable and toxic liquids and gases.

- Provide appropriate fire protection systems to rapidly bring under control and extinguish any reasonably foreseeable fire which could develop during normal operations.

- Minimize the potential for pollution of the environment from accidental spills, venting or flaring of hazardous materials.

The F&G system is used for automating emergency actions with a high-integrity safety and control solution to mitigate further escalation. It is also important for recovering from abnormal situations quickly to resume full production.

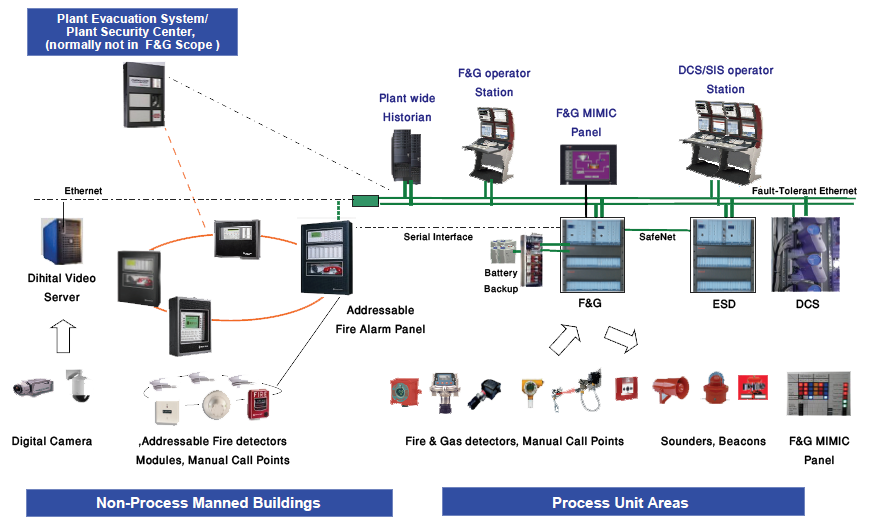

A typical F&G safety system comprises detection, logic control and alarm and mitigation functions. Control Panel is the central control unit of the overall F&G detection and control system. The controller receives alarm and status or analog signals from field monitoring devices required for Fire and Gas detection. The controller handles the required actions to initiate alarms and mitigate the hazard.

Fire and gas detection devices have developed greatly over recent years. Using new techniques and adding intelligence to these instruments to reduce the number of spurious alarms has greatly improved detection rates. Correct and proven connection of fire and gas detectors to plant safety systems is an important factor in reliable performance of the F&G system and for establishing the desired Safety Integrity Level (SIL).

Today, F&G detection systems are generally Programmable Electronic Systems (PES) type with high safety availability and mitigation effectiveness. As modern F&G systems are tightly integrated with the overall process safety strategy, mitigation either takes place via the Emergency Shutdown (ESD) system or directly from the F&G system itself.

Components of a Fire and Gas System |

| A good F&G system combines innovative fire and gas detectors, conventional and analog addressable fire panels, clean agent and inert gas fire suppression systems, and a SIL-certified fire and gas Control Panel into a consistently designed and executed solution. An integrated system provides common tools, operating interface and networking, resulting in a common platform with independent systems. F&G systems can detect early warnings of explosive and health hazards, including combustible and toxic gas releases, thermal radiation from fires and minute traces of smoke in sensitive equipment enclosures. They also provide audible and visual alarm indications helping to ensure operators and personnel are informed of potentially hazardous situations. The F&G system automatically initiates executive actions minimizing escalation of safety incidents and protecting personnel, property and the environment. Integration at the controller level provides plant-wide Safety Instrumented System (SIS) point data, diagnostics and system information, as well as alarms and events, operator displays and sequence of event information to any station. This minimizes intervention and shutdowns, reduces hardware costs, and allows plants to recover more easily from process upsets. The new generation of fire & gas solutions provides alerts of abnormal situations in a fast, accurate and structured way, giving personnel time to decide upon the correct course of action. These solutions include new integration capabilities with process simulation tools, F&G detectors and control communication protocols, enabling safety engineers to design and build large integrated and distributed plant-wide safety strategies. Overall SIS technology integrates safety measures dispersed throughout a plant to reduce risk to employees and assets, increase process availability, and improve regulatory compliance. SIS solutions can be integrated with fire & gas detectors for increased protection, and unified with third-party applications and systems to reduce validation and acceptance testing costs. Modern safety systems, seamlessly integrated with the plant automation system through a secure communication network, transfer alarm signals, fault signals and system diagnostics. Information from all related systems can be transferred, gathered and handled at the same location, and an additional layer can be achieved to monitor the status and operability of the total F&G detection and control system. |

|

Improve Plant Safety |

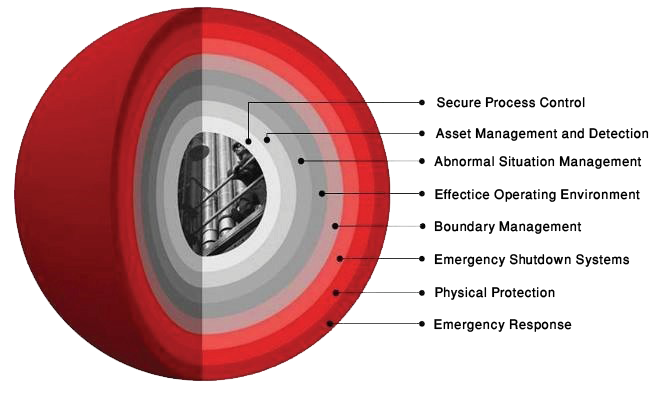

| A layered safety strategy encompasses process and system technology, and the people who interact with that technology, to help plants achieve their safety objectives.

A layered safety strategy unifies all plant protection layers (i.e., basic control, prevention and mitigation as outlined in IEC 61511 standard) required for achieving optimum functional safety. Plus, it provides the required functional safety with a high SIL. This includes superior visualization and logging facilities enabling optimal operator response and accurate evaluations. By integrating basic control, prevention and mitigation components, overall project costs and ongoing maintenance expenses can be vastly reduced. |

|

| Integrated Control and Safety Systems (ICSS) provide multiple benefits to process plants. For instance, they helps operators to minimize intervention and shutdowns and recover more easily from process upsets. They also allows facilities to reduce hardware and installation cost, and ensure easier system configuration with preconfigured function block selections.

Plants implementing an ICSS platform for F&G, ESD and DCS systems can significantly lower their operation and maintenance costs, and in many cases, reduce overall project costs by 25%. Seamless integration with the ESD and DCS via a common network protocol also provides a safe landing in case of emergencies and eliminates the need for additional equipment or engineering. Integration of fire detection & security systems for off-sites and utilities with the plant automation infrastructure further improves operator efficiency through single-window access for alarm visualization, diagnostics, and events/historians. At the core of a layered safety strategy is process design, the embodiment of the business, safety, and production considerations necessary for effective operations. At the next layer, this approach implements tools and procedures for managing abnormal situations and reducing incidents. When an abnormal situation occurs, alarm management, early event detection, and Abnormal Situation Management (ASM), designed displays ensure operators have the information available in the context they need it. This enables faster reaction to hazardous situations, thereby avoiding safety incidents. Next, properly designed Emergency Shutdown systems and automated procedures can move a plant to a safe state in the event an incident escalates beyond the inner sphere of protection. Should an incident occur, Fire and Gas detection solutions coupled with rapid location of individuals and a carefully designed emergency response procedure will help contain the impact. Finally, a layered approach to safety protects the perimeter of the plant using physical security that safeguards access to structures and monitors traffic approaching the facility. |

Emergency Shutdown System |

Emergency Shutdown (ESD) System are specialized highly reliable control systems for high risk industries like Oil and Gas, Nuclear Power or other Environments with explosion risk. Their purpose is to protect personnel, plant, and the environment in case the process goes beyond the control margins. Emergency Shutdown System (ESD) is designed to minimize the consequences of emergency situations, related to typically uncontrolled flooding, escape of hydrocarbons, or outbreak of fire in hydrocarbon carrying areas or areas which may otherwise be hazardous. There are several purposes of the ESD System which is:

Typically, the ESD System could fulfill the above objective by the following implementation:

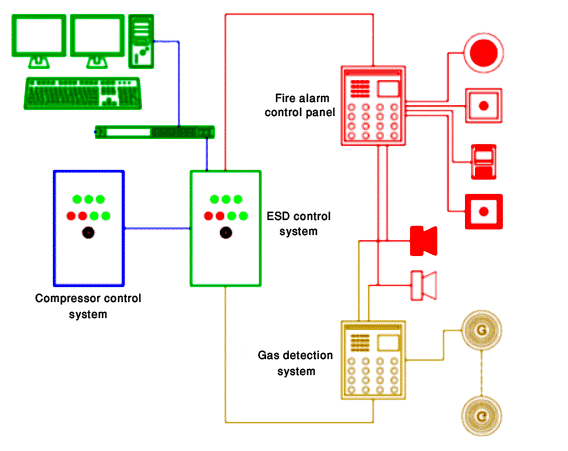

The integration of different systems like Fire and Gas system, compressor, DCS or other systems may vary from one industry to another. It depends on specific industry standards. The below figure is a simple example of ESD system integration. |

|

Applicable Notes

- The IEC 61511 standard (ANSI/ISA S84.01 in the U.S.) is a major step towards protecting industrial plants. This standard concerns the determination and development of Risk Reduction Measures (RRMs) required as the outcome of the Equipment Under Control (EUC) risk assessment. The basic principle of risk assessment is that all potential risks to the EUC are identified and analyzed. This includes calculating the probability of each potential EUC hazard and determining the risk reduction measures required to achieve an acceptable SIL.

- The potential risk of EUC hazards can be considered as the outcome of the probability that the hazard occurs, and the consequences of the hazard: Risk = Probability x Consequences

- The prescribed reduction measures either decrease the risk probability (e.g. ESD systems), or mitigate their consequences (e.g. F&G systems). The risk of EUC hazards can be reduced by a combination of several RRMs, where each measure takes care of a part of the total required Risk Reduction Factor (RRF).

- The Fire & Gas System shall have a communications integration with the Distributed Control System (DCS) in order to have Fire & Gas graphics and alarms for display to the operator, meanwhile, there shall be independent displays such as independent Human Machine Interfaces (HMI) to draw attention to fire & gas excursions when the DCS HMIs are not available; The plant Fire & Gas system, with fire system for occupied buildings, shall be integrated with Plant Evacuation and System/Site Security Centre for plant evacuation. As part of an overall plant safety strategy, end users need a unified platform for emergency shutdown and fire & gas detection to have a single window for operators and common tool for engineering and maintenance to drive down operational risk and costs.

Our Services

SISICO is able to offer an extensive range of Fire and Gas Systems and other related systems to suit your specific environment.