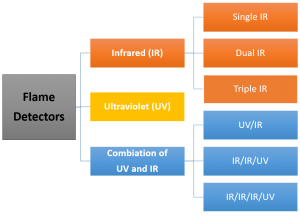

Flame Detector is a sensor designed to detect and respond to the presence of a flame or fire. Responses to a detected flame depend on the installation, but can include sounding an alarm, deactivating a fuel line, and activating a fire suppression system. The three most commonly recognized flame detection technologies are Infrared (IR), Ultraviolet (UV) and a combination of UV and IR Flame Detectors.

Single Frequency Infrared Flame Detector (IR): |

|

|

|

It is sensitive to a narrow band of radiation around the 4.4 micron range which is a predominant emission band for hydrocarbon fuelled fires. Additionally, the sun’s radiation at this band is absorbed by the earth’s atmosphere, making the IR flame detector solar blind. Single frequency detectors use a pyroelectric sensor, which responds to changes in IR radiation intensity. In addition they incorporate a low frequency band pass filter, which limits their response to those frequencies that are characteristic of a flickering fire. IR detectors are sensitive to most hydrocarbon fires (liquids, gases, and solids). Fires such as burning metals, ammonia, hydrogen and sulphur do not emit significant amounts of IR in the detector’s sensitivity range to activate an alarm. IR detectors are suitable for applications where hydrocarbon fires are likely to occur and high concentrations of airborne contaminants and/or UV radiation sources may be present. The detector should be used with caution when the presence of hot objects and the potential for ice buildup on the detector are likely. |

Advantages+ Highly immune to optical contaminants like oil, dirt, and dust + High speed response under 30 milliseconds for some brands + Insensitive to solar, welding, X-rays, lightning, sparks, arcs and corona |

Disadvantages– Generally not suitable for non-carbon fires – Some brands will respond to modulated infra-red sources – Rain, ice and water vapor on the detector lens will inhibit detection |

Multi Spectrum Infrared Flame Detector (IR3): |

|

|

Triple-IR flame detectors compare three specific wavelength bands within the IR spectral region and their ratio to each other. In this case one sensor looks at the 4.4 micrometer range while the other sensors look at reference wavelengths both above and below 4.4. This allows the detector to distinguish between non-flame IR sources and actual flames which emit hot CO2 in the combustion process. As a result, both detection range and immunity to false alarms can be significantly increased. IR3 detectors can detect a 0.1m2 gasoline pan fire at up to 65 m in less than 5 seconds. Triple IRs, like other IR detector types, are susceptible to blinding by a layer of water on the detector’s window. |

Advantages+ Virtually immune to false alarms + Fire response in the presence of modulated infra-red black body radiation with some brands + Long detection range |

Disadvantages– Typical response time is longer when compared to single frequency detectors |

Ultraviolet Flame Detector (UV): |

|

|

A UV detector uses a sensor tube that detects radiation emitted in the 1000 to 3000 angstrom range. It is important to note that ultraviolet radiation from the sun that reaches earth starts at 2800 angstrom. If the detector’s sensor has a wide range then it will be triggered by the sun’s rays, which means it is only suitable for indoor use. There are sensors available with a range of 1800 to 2500 angstroms. Virtually all fires emit radiation in this band, while the sun’s radiation at this band is absorbed by the earth’s atmosphere. The result is that the UV flame detector is solar blind. The implication of this feature is that the detector can be used indoors and outdoors. UV detectors are sensitive to most fires, including hydrocarbon (liquids, gases, and solids), metals (magnesium), sulphur, hydrogen, hydrazine and ammonia. The UV detector is the most flexible general purpose optical fire detector available. They are fast, reliable, have few false alarm sources and respond to virtually any fire. |

Advantages+ Responds to hydrocarbon, hydrogen and metal fires + High speed response + Solar insensitive |

Disadvantages– Will respond to welding at long range – May respond to lightning, X-rays, sparks, arcs, and corona – Some gases and vapors will inhibit detection – Some UV sensors have a wide detection range resulting in solar false alarms |

Ultraviolet / Infrared Gas Detector (UV/IR): |

|

|

A UV/IR detector consists of an UV and single frequency IR sensor paired to form one unit. The two sensors individually operate the same as previously described, but additional circuitry processes signals from both sensors. This means the combined detector has better false alarm rejection capabilities than the individual UV or IR detectors. Since the UV/IR detector pairs two sensor types, it will typically only detect fires that emit both UV and flickering IR radiation. UV detectors will respond to virtually all fires including hydrocarbon (liquids, gases, and solids), metals (magnesium), sulfur, hydrogen, hydrazine and ammonia. IR detectors typically only respond to hydrocarbon fires. Since the IR detector is not sensitive to burning metals, ammonia, hydrogen and sulfur the combined unit will not respond to these fires. |

Advantages+ Virtually immune to false alarms + High speed response – under 500 milliseconds + Solar, welding, lightning, X-rays, sparks, arcs, and corona insensitive |

Disadvantages– Not recommended for non-carbon fires – Some gases and vapors will inhibit detection due to blinding of the UV sensor |

Special Applications:

Dual Infrared Flame Detector (IR/IR): |

|

|

Dual IR (IR/IR) flame detectors compare the threshold signal in two infrared ranges. Often one sensor looks at the 4.4 micrometer carbon dioxide (CO2), while the other sensor looks at a reference frequency. Sensing the CO2 emission is appropriate for hydrocarbon fuels; for non-carbon based fuels, e.g., hydrogen, the broadband water bands are sensed. |

Multi Infrared ad Ultraviolet Flame Detector (3IR+UV): |

|

|

Multi-Infrared detectors use algorithms to determine the presence of fire and tell them apart from background noise known to as “Black-body Radiation”, which in generally reduce the range and accuracy of the detector. Black-body Radiation is constantly present in all environments, but is given off especially strongly by objects at high temperature. This makes high temperature environments, or areas where high temperature material is handled especially challenging for IR only detectors. Thus, one additional UV band sensor is sometimes included in flame detectors to add another layer of confirmation, as black body radiation does not impact UV sensors unless the temperature is extremely high, such as the plasma glow from an Arc welding machine. |

Applicable Notes:

- To positioning the Flame Detectors, related standards such as NFPA 72 or EN54 shall be considered.

- Flame detectors are typically used in open areas outdoors, but can also be used indoors

- Used to protect high risk areas such as oil rigs, fuel stores, petro-chemical plants, hangers, etc.

- Hot objects (engines/exhausts/heaters) are potential false alarm sources, including the Sun.

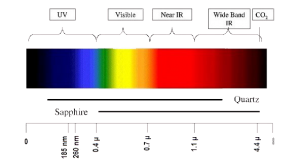

- Light spectrum is the many different wavelengths of energy produced by a light source and can be categorized as below:

Our Services:

SISICO is able to offer an extensive range of Flame Detectors to suit your specific environment from below mentioned companies: