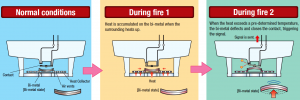

Heat Detector is a fire alarm device designed to respond when the convicted thermal energy of a fire increases the temperature of a heat sensitive element. Heat detectors, regardless of their communication method, Addressable or conventional, have two main classifications of operation, Fixed Temperature and Rate of Rise (ROR).

Fixed Temperature Heat Detector: |

||

|

It is activated when the ambient temperature rises more than a particular set point. There are two types of Fixed Heat Detectors: Electronic and Mechanical. Electronic Heat Detectors sense heat by making use of a thermistor, which is essentially a device that alters resistance when there is a change in temperature. Mechanical Heat Detectors are worked based on Bimetallic and contain a metallic strip with two different metals, each having a different temperature coefficient of expansion. As the heat reaches the strip, the metal warps and the contact is closed. |

|

|

Mechanical Fixed Temperature Heat Detectors:

|

||

|

Advantages of Fixed Heat detection + More reliable than smoke detector units + Not affected by dusty or dirty environments |

Disadvantages of Fixed Heat detection – Slower to respond than smoke detectors – Only suitable for protection of property |

|

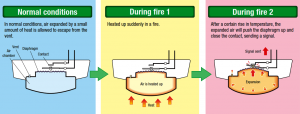

Rate of Rise Heat Detector (ROR): |

||

|

It is activated when the ambient temperature rises at a predetermined rate that is set during the manufacturing of the device. There are two types of Fixed Heat Detectors: Electronic and Mechanical. Electronic Heat Detectors sense heat by making use of a thermistor, which is essentially a device that alters resistance when there is a change in temperature. Mechanical Heat Detectors are worked based on Pneumatic. There is a flexible diaphragm that is sealed within an air chamber. The air chamber is constructed with a calibrated leak so that normal temperature. During a fire, the air temperature rises at a rate faster than normal, causing an increase on the room side of the diaphragm. The leak cannot compensate, and therefore the diaphragm moves and closes the detector contacts. |

|

|

Mechanical Rate of Rise Heat Detectors:

|

||

|

Advantages of Rate of Rise Heat Detectors + Responds faster than fixed temperature detector + Not affected by dusty or dirty environments |

Disadvantages of Rate of Rise Heat Detectors – Slower to respond than smoke detectors – Only suitable for protection of property |

|

Special Applications:

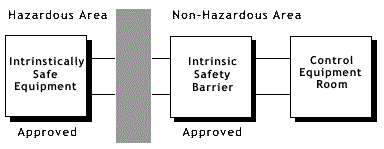

Intrinsically Safe Heat Detector: |

|

|

It is used in hazardous locations where explosive levels of gas or vapors are normally or potentially present. Intrinsically safe detectors must be compatible with the system control panel for proper use. An intrinsically safe barrier must be installed at the point where the intrinsically safe circuit connects to the fire alarm control panel. The barrier limits the available voltage and current available on the circuit to safe levels.

|

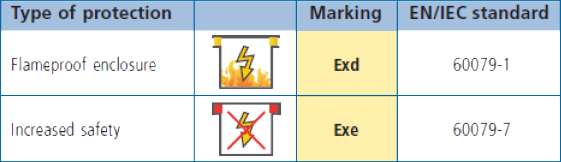

Explosion Proof Heat Detector: |

|

|

|

Electrical equipment sometimes must be installed in areas where combustible vapors and gases are used or may be present. These are commonly referred to as hazardous locations. When equipment must be installed in hazardous locations, there are strict requirements for the construction of the installation, including materials and design requirements. An Explosion Proof classification for a sensor/transmitter means that the housing has been engineered and constructed to contain a flash or explosion. Such housings are usually made of cast aluminum or stainless steel and are of sufficient mass and strength to safely contain an explosion should flammable gases or vapors penetrate the housing and the internal electronics or wiring cause an ignition.

|

Heat Detector Classifications

New EN54-5 classifications for heat detectors have introduced a new code for working out what Class of heat detector you are using. They now come with suffixes such as A1R and CS. This can be a bit of a mine-field so here are the classifications to help you work it out.

| Detector Classification | Typical Application Temp (°C) | Temperature Response Range (°C) |

| A1 | 25 | 54-65 |

| A2 | 25 | 54-70 |

| B | 40 | 69-85 |

| C | 55 | 84-100 |

| D | 70 | 99-115 |

| E | 85 | 114-130 |

| F | 100 | 129-145 |

| G | 115 | 144-160 |

Suffix “S” indicates the detector will not respond below the minimum static response temperature i.e. fixed temperature

Suffix “R” indicates that the detector has the ability to produce an alarm within the range of Rate of Rise of air temperature.

Applicable Notes:

- To positioning the Heat Detectors, related standards such as NFPA 72 or EN54 shall be considered. However the coverage of Spot-type Heat Detectors can be considered as 56 m2.

- In case of a fire that builds up and spreads slowly, the ROR heat detector may not be effective.

- Pneumatic heat detectors are commonly used in severe environments as they can be protected against the corrosive and harsh elements.

- To prevent inadvertent ignition of flammable gases and vapors by electrical equipment, the two most common methods of protection are Explosion Proof (denoted by “d or e” in the ATEX and IECEx Explosion Classifications) and Intrinsically Safe (denoted by “i”).

- Combination rate-of-rise and fixed temperature thermal detectors are also manufactured and have both technologies built in.

Our Services:

SISICO is able to offer an extensive range of Heat Detectors to suit your specific environment from below mentioned companies: