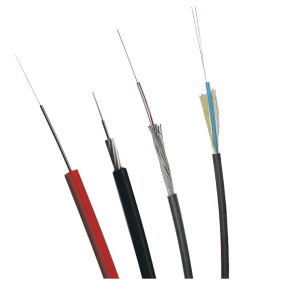

Linear Heat Detector (LHD) is a line-type form of conventional fixed temperature heat detection. This linear cable can detect a fire anywhere along its entire length and is available in multiple temperatures.

Linear Heat detectors have three main classifications of construction and operation: Analogue, Digital and Fiber Optic

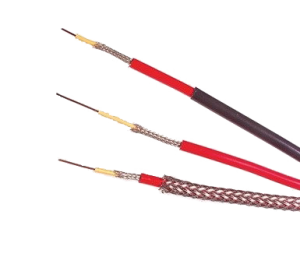

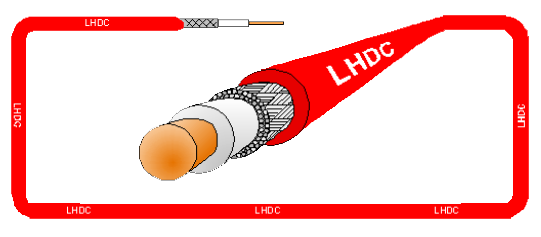

Analogue Linear Heat Detector |

|

|

|

It is a coaxial cable constructed with a copper coated steel central conductor, an inner insulation, a tinned copper braid layer and an overall protective sheath. The primary mechanism of heat detection is that the resistance of the dielectric is monitored between the central conductor and braid layer. Analogue heat detection wire is employed in conjunction with an end of line terminating device for continuity monitoring and a zone monitoring controller providing adjustable alarm thresholds and Fire and Fault outputs.

|

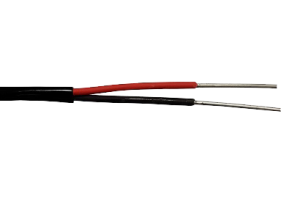

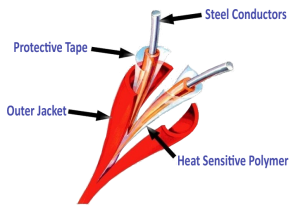

Digital Linear Heat Detector |

|

|

|

This detection system is essentially a cable terminated by an end of line resistor which has two conductors, separated by a polymer plastic, that have a specific melting point. This melting point is in correspondence with the set point. When the temperature rises to a point where the insulation of the two conductors melt, the conductors come into contact with one another and shorting occurs which causes the alarm to be sounded. Linear heat detectors are quite popular in industrial locations as they can cover large areas.

|

Fiber Optic Linear Heat Detector |

|

|

|

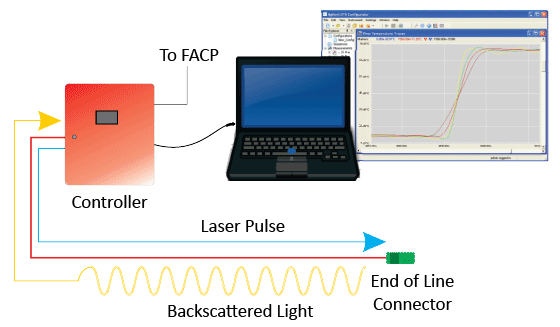

Fiber Optic Linear Heat Detector is a real-time temperature monitoring system consisting of Fiber Optic sensor cable and Controller with related software. This functions on the principles of back scattered light from a laser beam pulse sent down the fiber cable. The controller calculates the temperature using the ratio between stoke and anti-stokes frequency bands. Temperatures are recorded along the sensor cable as a continuous profile and the system is capable of detecting fire and overheat conditions over distances up to kilometers. The controller can be configured for various alarm criteria and can be connected to a fire alarm control panel using relay inputs and outputs.

|

Applicable Notes

- For detail specifications, please refer to manufacturer’s instruction and datasheets.

- The resistance of End of Line Resistor varies with application.

- The Fusible polymer plastic of digital linear heat detectors is not self-restoring and is non-resettable. But, Analogue Linear Heat Detector and Fiber Optic Linear Heat Detector are restorable and resettable.

- The outer jacket shall be made of material that resists corrosion, chemicals, moisture etc.

- Linear Heat detectors cannot really be termed as Life Safety Equipment. They can be used to protecting your buildings and property from damage due to fire.

- The Fiber Optic Linear Heat Detector is safe to use in hazardous environments as there is no electric current used in the sensing fiber and the fiber is relatively inert and dielectric medium. Also they are immune to all EMI and RFI.

- Fiber Optic Linear Heat Detectors are commonly used to protect tunnels, metro, conveyor belts, cable trays and transformers, etc.

- Alarm criteria and zone sizes can be configured in Fiber Optic Linear Heat Detectors.

Our Services

SISICO is able to offer an extensive range of Linear Heat Detectors to suit your specific environment from below mentioned companies: